Oil and Gas Resistant Shielded Cables in Automated Fueling Processes

Modernizing Fueling Systems: The Role of Oil and Gas Resistant Shielded Cables

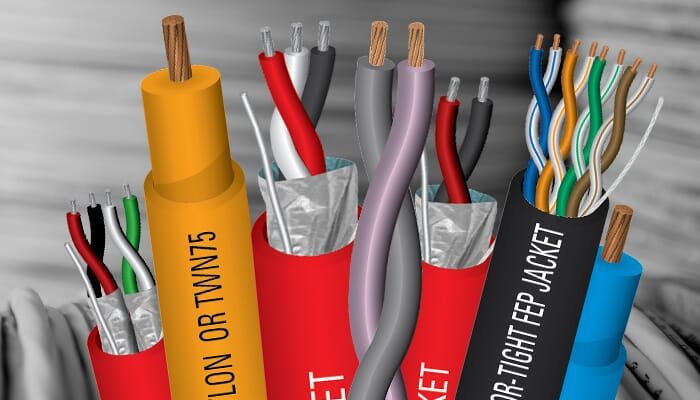

The rapid advancement of technology in the fueling industry has ushered in an era where efficiency and safety are paramount. At the heart of this evolution lies the integration of oil and gas resistant shielded cables, crucial components in automated fueling processes.

These cables signify a substantial advancement in guaranteeing dependable and secure operations within an industry progressively reliant on automation to achieve efficiency and accuracy. The question arises: How exactly are oil and gas resistant shielded cables revolutionizing automated fueling processes? Their role extends beyond mere connectivity; they are pivotal in maintaining system integrity in the harsh environments characteristic of the oil and gas industry.

Fueling the Future: The Advent of Automated Fueling Technology

The emergence of Automated Fueling Technology marks a transformative era in the oil and gas industry, fundamentally changing how fueling operations are conducted. This technology, characterized by its high efficiency and enhanced safety features, has been rapidly adopted across the sector. At its core, Automated Fueling Technology streamlines processes, reduces human error, and significantly improves operational safety. One of the key elements enabling this technological leap is incorporating sophisticated cabling solutions, where companies like us at Windy City Wire play a pivotal role.

With our commitment to innovation since 1994, Windy City Wire has been at the forefront of providing advanced low-voltage wire and cable products. These products are components and comprehensive solutions that seamlessly integrate Automated Fueling Technology.

Our company’s offerings, ranging from SmartWire® cables to RackPack® Field Systems Solutions, demonstrate a deep understanding of the industry's needs. These solutions facilitate physical connectivity and contribute to the overall system’s efficiency and reliability. Ensuring consistent and secure data and power transmission is integral to the safety and efficiency enhancements that Automated Fueling Technology promises. In essence, Windy City Wire’s large ecosystem of products embody a synthesis of technological excellence and practical application, making them indispensable in modernizing fueling systems.

Enhancing Safety and Reliability: Gas Resistant Cables in Automation

In the intricate web of automated fueling systems, the role of gas-resistant cables is both critical and multifaceted. Industrial Gas And Oil Resistant Pair Cabling, a specialized offering from Windy City Wire, exemplifies the innovation required to meet the demanding conditions of the oil and gas sector.

These cables are engineered to withstand the corrosive and hazardous environments typical in fueling processes, ensuring uninterrupted and safe operations. Their resistance to gas and oil exposure not only enhances the longevity of the cabling system but also significantly mitigates risks associated with leaks and spills.

Windy City Wire's focus on producing these robust cables stems from a deep understanding of the industry’s unique challenges. Our products are tailored to ensure maximum reliability and safety in data, voice, and video applications. These cables form the backbone of the automated systems, transmitting crucial operational data and ensuring the integrity of safety protocols. The importance of such reliable cabling cannot be overstated in an industry where even a minor failure can have substantial consequences.

By providing these gas and oil-resistant solutions, Windy City Wire enhances the functionality of automated fueling systems and reinforces the industry's commitment to safety and reliability. Our innovative approach to cable manufacturing has set new standards in the industry, making us a key player in the technological evolution of automated fueling processes.

The Backbone of Automation: Solid Pair Cables for the Oil and Gas Sector

Within the intricate architecture of automated fueling systems, Solid Pair Cables for gas and oil and Oil And Gas Resistant Power Cables from Windy City Wire emerge as vital components. These cables guarantee the dependability and effectiveness of these complex systems by serving as the backbone of automation. Designed to meet the rigorous demands of the oil and gas industry, these cables withstand extreme environmental conditions, from exposure to harsh chemicals to fluctuations in temperature.

The significance of these cables extends beyond mere functionality. They are a testament to our commitment to innovation and excellence. With their robust design, these cables ensure minimal downtime and maximum performance, which is crucial in an industry where every second counts. The integration of these high-quality cables into automated fueling systems exemplifies the company’s dedication to advancing technology in the oil and gas sector.

Our products facilitate the smooth operation of these systems and play a critical role in pushing the boundaries of what is possible in fueling automation. Windy City Wire’s solid pair cables embody the synthesis of durability and technological sophistication, making them indispensable in the evolution and efficiency of automated fueling processes.

Windy City Wire: Pioneering Cable Solutions for the Oil and Gas Industry

We have highlighted in this article the integral role of oil and gas resistant shielded cables in automated fueling processes, underscoring our significance in enhancing safety and efficiency.

Established in 1994, Windy City Wire has been at the forefront of this industry, providing a diverse selection of cutting-edge cable solutions. Our wide range of products, including the Industrial Gas And Oil Resistant Pair Cables and Solid Pair Cables, have been recognized for their exceptional quality and performance in the industry. Windy City Wire is known for its dedication to delivering high-quality cabling solutions that cater to the specific needs of the oil and gas industry.

Our expertise and innovative approach have established us as a trusted leader in the field. The increasing evolution of the industry places greater significance on the contributions of businesses such as Windy City Wire, which advance technology and guarantee operational safety. For those in need of reliable and efficient low-voltage wire and cable solutions in the gas and oil industries, Windy City Wire stands as the go-to partner.