Why High-Performance UST Cables Are Essential for Environmental Safety

The integrity of underground storage tank (UST) systems depends on the quality of their components, and one of the most crucial elements is the cabling. Selecting the right UST cables, specifically those with high-performance features, can mean the difference between operational safety and an environmental disaster.

High-performance UST cables, designed to withstand exposure to harsh chemicals, moisture, and other underground environmental stressors, help safeguard the environment, maintain compliance with regulatory standards, and protect valuable infrastructure.

The Critical Role of UST Cables in Environmental Safety

UST cables play a significant role in keeping underground storage tank systems safe and reliable. Because they are exposed to elements that can degrade materials, specialized UST cables are essential in preventing hazardous leaks, spills, or failures that could harm the environment.

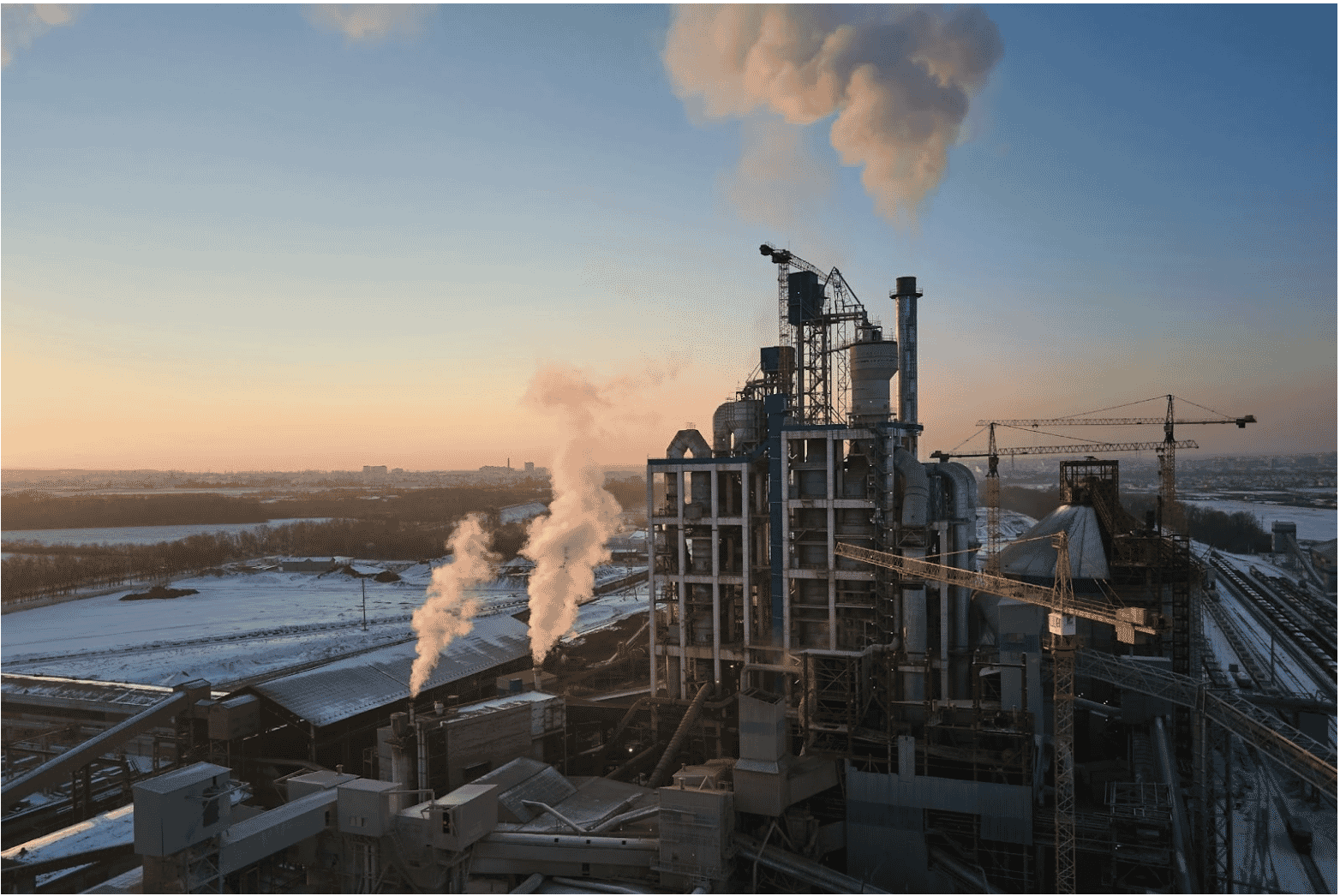

Environmental safety has become central to the industrial sector, with sustainability gaining momentum as a corporate responsibility and a regulatory demand. Selecting high-performance UST wiring supports this goal by minimizing risks, protecting natural resources, and ensuring that companies meet environmental regulations.

Key Features of Gas and Oil Resistant Cables

Not all cables are suitable for the demanding conditions that underground storage tanks face. Here’s why gas and oil-resistant cables stand out.

Chemical Resistance

High-performance UST cables resist the damaging effects of chemicals and other corrosive substances. Since underground storage systems often deal with petroleum, gasoline, and other potentially harmful chemicals, UST cables must withstand prolonged exposure to such substances. Chemical-resistant UST cables prevent degradation and help avert leaks that could have harmful environmental consequences.

Corrosion Resistance

Soil composition, moisture, and other environmental factors introduce corrosion risks to underground cabling systems. Corrosion can cause extensive damage over time, weakening the integrity of standard cabling. High-performance UST cables that resist corrosion provide reliable, long-lasting performance, reducing the likelihood of failures that could disrupt operations or cause environmental contamination.

Durability Against Temperature and Mechanical Stress

Underground environments often experience temperature extremes that can strain wiring materials. High-performance UST cables resist these fluctuations, avoiding issues like expansion, contraction, or melting that can impair performance. Additionally, UST cables endure mechanical stress from shifting soil or minor underground movements, making their durability a critical factor.

Low-Smoke, Halogen-Free (LSZH) Jackets

Many high-performance UST cables incorporate LSZH materials, which release minimal smoke and toxic gasses in the event of a fire. This feature enhances safety by reducing potential hazards to workers or nearby environments, aligning with environmental standards that prioritize safety and sustainability.

Together, these features allow gas and oil-resistant cables to provide the resilience and durability that complex underground storage systems demand.

Environmental Challenges Faced by Underground Storage Systems

UST cables must withstand unique and challenging environmental conditions, especially in demanding industrial or commercial applications. Let’s examine some of these environmental threats.

Chemical Exposure

Underground storage tanks and pipelines can contain various chemicals, including petroleum, gasoline, and solvents. Standard wiring may degrade when exposed to such substances, leading to potential system failures. Oil-resistant UST wiring protects against these chemicals, preventing degradation and supporting long-term performance.

Corrosive Soil and Groundwater

The composition of soil and groundwater can expose UST cables to corrosive elements that quickly erode traditional cabling materials. Corrosion-resistant UST cables mitigate this risk by offering reliable performance and reducing the maintenance demands on underground systems, especially in regions with high moisture or corrosive soil compositions.

Temperature Extremes

Underground environments are not immune to temperature fluctuations. Areas near geothermal sources or certain climates may expose cables to extreme heat or cold. High-performance UST cables, engineered to withstand temperature variations, support system longevity by resisting thermal expansion or contraction. This resilience helps maintain uninterrupted functionality and reduces risks to critical infrastructure.

These environmental challenges underscore the need for specialized UST cabling solutions that can withstand harsh underground conditions without compromising performance.

Regulatory and Compliance Considerations

Environmental compliance is a non-negotiable aspect of any operation using underground storage systems (USTs). Regulations surrounding UST systems have evolved to prioritize operational safety and environmental protection, focusing on standards that prevent leaks, contamination, and fires. Selecting UST cables that meet regulatory standards ensures that underground storage systems operate within the law and align with best practices for sustainability.

Cables used in UST applications should meet industry standards for chemical resistance, fire safety, and corrosion protection. Non-compliant cables expose a company to penalties and legal consequences and can increase the likelihood of environmental damage. Choosing gas and oil-resistant UST cables that meet these standards signals a commitment to environmental stewardship, protects valuable assets, and positions a business as a responsible industry player.

The Long-Term Benefits of Corrosion-Resistant UST Cables

Investing in high-quality, corrosion-resistant UST cables offers companies long-term advantages. Let’s take a closer look at the economic and operational benefits:

Reduced Maintenance Costs

Cables that resist the effects of moisture, chemicals, and other environmental factors require less frequent replacement and lower maintenance expenses. By reducing the need for constant upkeep, corrosion-resistant UST cables lessen the total cost of ownership over the system's lifespan. Companies benefit from cost savings while also enjoying consistent performance.

Extended Infrastructure Lifespan

High-quality, corrosion-resistant cables enhance the durability of entire underground storage tank systems. They can withstand degradation over time and support the longevity of critical infrastructure. Companies with long-term maintenance strategies benefit from fewer replacements, uninterrupted service, and a lower environmental footprint, as robust materials reduce waste.

Operational Continuity and Environmental Protection

Coronary-resistant cables offer critical advantages for companies that prioritize sustainability and operational stability. Their ability to withstand harsh conditions means less downtime, fewer disruptions, and a reduced chance of hazardous incidents. These cables are not only part of a system’s design but are vital components in an operation’s overall commitment to environmental and community safety.

Incorporating corrosion-resistant cables is an investment in infrastructure and environmental responsibility, demonstrating a proactive approach to operational stability and sustainability.

Choosing High-Performance UST Cables for Environmental and Operational Integrity

Selecting the right underground storage tank cables for underground storage tank systems means balancing performance, durability, and environmental responsibility. When choosing high-performance UST cables, companies should consider the following factors:

Chemical and Corrosion Resistance

The cable’s resistance to chemicals and corrosion is a primary consideration, especially when the system involves hazardous materials. Ensuring that cables can withstand prolonged chemical exposure and resist corrosion helps prevent failures and supports safe, reliable operation.

Temperature and Mechanical Durability

Underground cables must perform consistently across various temperatures and handle mechanical stress. Cables that meet these demands ensure uninterrupted performance, even under challenging conditions.

Compliance with Regulatory Standards

Compliance with environmental and safety standards is crucial. Choosing cables that meet industry guidelines for underground storage tank systems supports regulatory adherence and minimizes the risk of environmental incidents that could harm communities or result in fines.

Investment in Long-Term Solutions

Investing in high-performance UST cables provides long-term financial benefits by reducing replacement and maintenance costs—companies prioritizing long-term durability over short-term savings benefit from consistent performance and lower lifetime expenses.

The suitable UST cable protects operations and reinforces a company’s commitment to environmental safety and regulatory compliance.

Buying High-Performance UST Cables

High-performance UST cables are essential for maintaining safe, reliable underground storage systems. As companies seek to balance operational demands with environmental responsibility, selecting suitable gas and oil-resistant UST cables becomes increasingly essential. Corrosion-resistant, durable UST cables prevent failures, reduce environmental risks, and align with regulatory standards, ultimately supporting sustainability goals.

For companies aiming to invest in sustainable and resilient UST solutions, prioritizing quality and reliability in cable selection is a crucial step. Explore our Gas & Oil Resistant Resource Center or contact the team here at Windy City Wire for more information on high-performance UST wiring solutions that meet the most demanding operational and environmental needs.