The Role of UV-Resistant Wiring in Outdoor Applications

Direct sunlight can be one of the most punishing elements a cable system faces over time. We’ve seen what happens when wiring isn’t built to withstand the ultraviolet (UV) rays that bombard exposed surfaces daily. Jackets crack, colors fade, and systems fail. In the world of long-term infrastructure, that's cosmetic damage and a potential weak point in the system.

That’s where UV-resistant outdoor wiring makes a real difference. When cables must perform reliably in sunlight-exposed environments, material quality becomes mission-critical. UV-resistant jackets help preserve the integrity and performance of the wiring underneath, supporting safety, longevity, and signal continuity over the long haul.

Whether we’re working on power runs, AV signal paths, or low-voltage control lines, one constant remains true: exposure to UV rays accelerates degradation. Teams working on commercial infrastructure often underestimate how quickly untreated cable jackets can fail. Once jacket integrity goes, performance issues are rarely far behind.

How Sunlight Damages Electrical Cables

Standard cable jackets don't consider long-term sunlight. Constant exposure to UV radiation causes real physical changes to the materials. We’ve seen examples of cable jackets that once looked strong and flexible becoming brittle, faded, or cracked after prolonged exposure.

Sunlight breaks down molecular bonds in plastics and rubbers. That kind of degradation can lead to:

- Surface cracking and chalking

- Color fading that reduces visibility or identification

- Jacket splitting, exposing the insulation or conductors inside

Without UV protection, even thick cable jackets can lose their durability faster than expected. Once compromised, the cable is at greater risk for moisture intrusion, mechanical failure, or signal degradation. While minor flaws might go unnoticed, small issues can lead to bigger failures in high-traffic, critical systems.

That’s why sunlight-resistant cables make such a noticeable difference in exposed environments. A UV-protected electrical wire includes jacket materials that resist this kind of damage. These materials are often stabilized using chemical additives that deflect or absorb UV rays before they can break down the surface.

UV degradation is often slow and subtle, making it easy to overlook until a cable fails prematurely. The best way to prevent that outcome is by starting with wiring designed to withstand long-term exposure.

What Makes Outdoor Wiring UV-Resistant?

UV-resistant outdoor wiring starts with the right jacket material. Our team often looks for options tested and rated specifically for prolonged exposure to sunlight and weather. Common materials for UV resistance include:

- Sunlight-resistant PVC: A widely used material that incorporates stabilizers to resist UV-related breakdown.

- Polyethylene (PE): Known for its high durability and natural resistance to UV and environmental stress.

We’ve also found that weatherproof wiring solutions typically undergo accelerated weathering tests. These tests simulate long-term sunlight exposure using UV lamps and extreme conditions. When a product passes, it demonstrates that the jacket can retain its physical properties and color over time.

Material selection affects more than surface appearance. Durable outdoor wiring also helps prevent internal issues, such as conductor corrosion or insulation deformation. When a cable retains its jacket strength, it also protects the signal and power flow inside.

This durability can directly reduce the need for early replacement or repair for long-term projects, saving time and money and preventing unnecessary system downtime.

UV-resistant wiring also often includes features that contribute to overall environmental protection. Some jacket materials resist light, chemicals, oil splashes, and water intrusion. This combination of traits makes these cables more reliable in demanding conditions.

Applications That Require UV-Resistant Cables

UV-protected electrical wire supports a wide range of environments where sun exposure is either constant or intermittent. Even partial or indirect sunlight can damage unprotected wiring, especially over several years.

Here are a few areas where we’ve seen UV-resistant outdoor wiring used effectively:

1. Rooftop Security Systems

Cameras, sensors, and controllers mounted on rooftops often rely on exposed cabling. Even with partial shading or conduit, UV resistance helps cables maintain jacket flexibility and function for the life of the system.

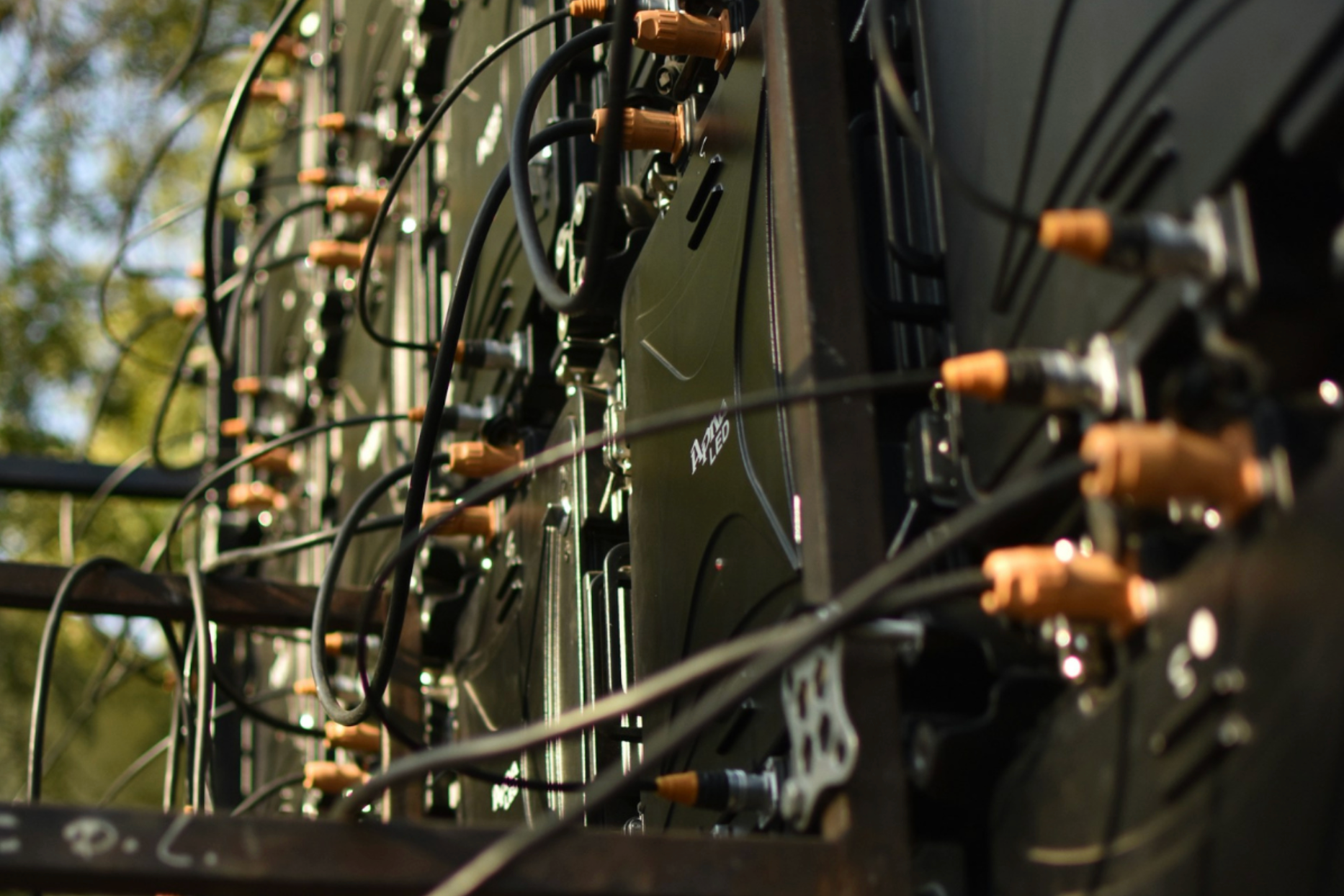

2. Outdoor AV Setups

Sound systems, displays, and media feeds for outdoor events or commercial signage need signal cables that won’t degrade under sunlight. UV-resistant jackets help keep performance sharp and signal loss low.

3. Exterior Access Control Systems

Card readers, intercoms, and gate controllers often connect to centralized systems via cables that run along walls or fences. These setups benefit from sunlight-resistant cables that won’t crack or fail due to daily sun exposure.

4. Direct Exposure on Building Exteriors

Weatherproof wiring solutions are essential when conduits or trays run along walls, rooftops, or between structures. UV-rated cables keep systems working even when sunlight exposure is unavoidable.

5. Utility and Infrastructure Zones

Even shaded cables can experience indirect UV stress in open-air mechanical yards or utility platforms. Full exposure doesn’t take long to begin degrading standard jackets, so UV resistance is often recommended even in partially covered areas.

Choosing Durable Wiring That Performs Outdoors

For teams sourcing materials for long-term infrastructure, it’s about what a cable does and how long it lasts. We focus on offering durable outdoor wiring that supports reliable performance in exposed environments without constant maintenance.

When reviewing product specs, it’s worth looking for:

- UV-rated jackets that specifically mention sunlight resistance

- Outdoor-rated or sunlight-resistant certifications from trusted third-party labs

- Construction materials are known for long-term durability (e.g., PE or PVC)

Some teams also examine abrasion resistance, chemical resistance, and temperature tolerance. These factors are important in environments where sunlight is only one of several stressors.

The combination of third-party testing, jacket material properties, and real-world performance data all contribute to selecting a cable that can handle the job. When teams factor UV exposure into cable selection early in planning, they help minimize the risk of unexpected failures later.

We offer a range of UV-resistant outdoor wiring options designed to meet both electrical performance and material durability benchmarks. These products help support strong system uptime by withstanding harsh light exposure and physical wear.

If you're reviewing products, start with our Outdoor Cable collection.

Ensuring Long-Term Cable Reliability

UV-resistant outdoor wiring offers cosmetic benefits and protects electrical systems from failure caused by sun damage. As systems stretch across rooftops, across building exteriors, or along perimeter fencing, cable jackets face constant light exposure.

By selecting sunlight-resistant cables tested for these challenges, teams add a layer of protection that supports performance, safety, and longevity. Material choice is critical in reducing lifecycle costs and avoiding premature cable failure.

Our team is always ready to help you evaluate options. You can contact us directly for product information, or we can help you identify cables that meet your durability and environmental requirements.