The Key to Success for Fueling and Electrical Contractors

In the intricate world of fueling and electrical contracting, the choice of cables is not just a matter of preference but a critical decision impacting safety, efficiency, and project success. This is especially true in the oil and gas industry, where performance requirements and harsh environmental conditions necessitate the use of the most advanced cable technology.

Why is it crucial for contractors to choose the right oil and gas resistant shielded cables? The answer lies in the unique challenges the oil and gas industry poses: extreme temperatures, exposure to chemicals, and the need for uninterrupted operation in high-stress environments.

Selecting cables that can withstand these conditions while ensuring safety and reliability is essential. With its longstanding expertise in manufacturing and distributing top-tier low-voltage cables, Windy City Wire stands as a beacon of innovation and quality in this sector.

Our range of products, including oil and gas-resistant solid cables, is not just a commodity but a comprehensive solution tailored to meet the stringent demands of fueling and electrical contractors. This blog explores the significance of cable selection and provides guidance on their upkeep to ensure their continued effective operation and security.

Maintaining Efficiency: Oil and Gas Cable Maintenance and Repair Tips

The longevity and performance of oil and gas cables hinge critically on regular maintenance and timely repairs. In the relentless environment of oil and gas operations, cables are exposed to factors like extreme temperatures, abrasive chemicals, and physical stress. This exposure can lead to insulation breakdown, shielding damage, and cable failure.

Understanding and implementing proper maintenance and repair protocols is pivotal. The key to maintaining these cables lies in regular inspections. Periodic checks for signs of wear and tear, such as cracks in the insulation or exposed wires, can prevent minor issues from escalating into major failures. Another essential practice is to ensure that cables are correctly installed and supported to minimize stress and strain.

In terms of repairs, it's crucial to address any damage immediately to prevent operational downtime. Using high-quality repair materials that match the cable's original specifications ensures that the cable's integrity and performance are not compromised. Moreover, contractors should adhere to industry standards and manufacturer guidelines during maintenance and repair.

Windy City Wire's commitment to quality in products like Gas and Oil Resistant Solid Cables and Solid Core Cables for Gas and Oil is evident in their durability and reliability, making them an excellent choice for these demanding applications. By following these oil and gas cable maintenance and repair tips, contractors can ensure their cabling systems remain efficient, safe, and functional over extended periods, thereby safeguarding their investments and operations.

Installation Essentials: Guidelines for Oil-Resistant Cables

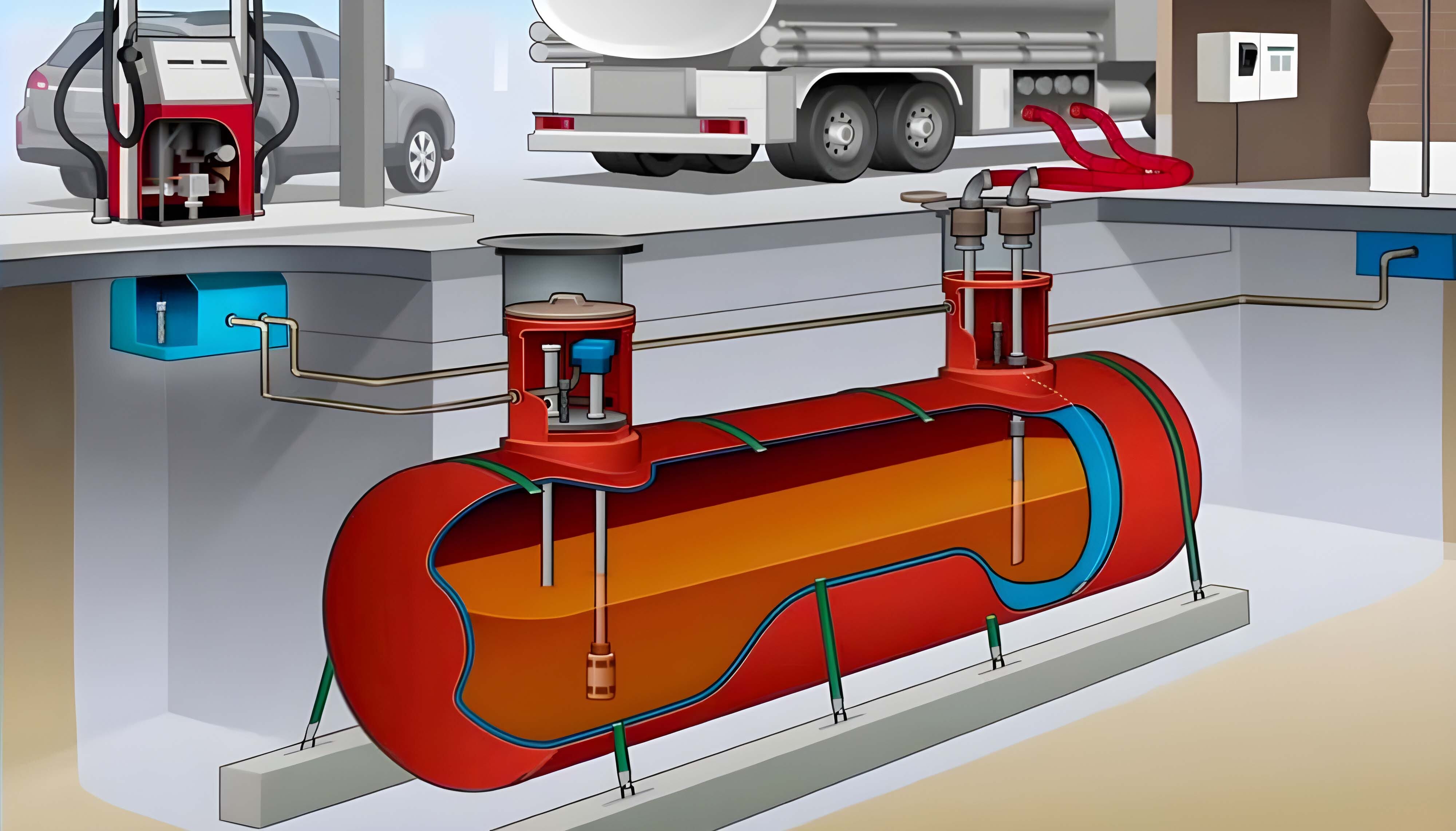

The installation of oil-resistant cables is a critical process that demands meticulous attention to detail and adherence to specific guidelines. These cables, designed to withstand the harsh conditions in the oil and gas sector, play a pivotal role in ensuring uninterrupted operations and safety.

One of the primary installation guidelines for oil-resistant cables is selecting the right type of cable for the specific environment. This selection involves considering factors such as temperature range, chemical exposure, and mechanical stress. Windy City Wire offers an extensive range of oil and gas-resistant solid cables, including Solid Core Cables for Gas and Oil, engineered to meet these diverse requirements.

Once the appropriate cable is selected, following best practices for cable routing and handling is crucial. Cables should be laid out to avoid sharp bends and undue stress, which could compromise their structural integrity.

Proper cable support and securing techniques are also essential to prevent physical damage over time. Another key aspect is ensuring that the cable terminations and connections are made securely and in accordance with industry standards. This step is vital to maintaining the cable's performance and longevity.

Furthermore, it is advisable to conduct thorough testing of the cable system post-installation. This helps identify potential issues early on and ensures that the system functions as intended. Adhering to these installation guidelines for oil-resistant cables, fueling, and electrical contractors can significantly enhance their operations' safety, efficiency, and reliability, aligning perfectly with Windy City Wire’s commitment to providing solutions that cater to the exacting needs of the oil and gas industry.

Optimizing Durability: The Use of Solid Core Cables in Oil and Gas

The adoption of solid core cables for gas and oil, including gas and oil-resistant solid cables, is a strategic decision for any fueling or electrical contractor aiming for long-term operational efficiency and reliability.

These cables are specifically designed to withstand the harsh environments typical in the oil and gas industry, where exposure to aggressive chemicals, extreme temperatures, and mechanical abrasions is a daily challenge. The robust construction of these cables ensures that they are not only resistant to oil and gas but also offer enhanced durability, reducing the frequency of replacements and maintenance interventions.

The benefits of using solid core cables in oil and gas applications are manifold. Firstly, they offer superior mechanical strength, which is crucial in environments where cables are subject to constant movement or heavy loads. This strength ensures that the cables maintain their integrity and performance over time. In the oil and gas industry, where operational continuity is of the utmost importance, the solid core design of the cables further improves their electrical performance by ensuring consistent and dependable transmission of power and signals.