Innovations in Refinery Safety with Oil and Gas Resistant Shielded Cables

Advancing Refinery Safety: The Role of Oil and Gas Resistant Shielded Cables

Safety remains a paramount concern in the dynamic world of refinery operations, continuously driving innovations in protective technologies. Among these advancements, oil and gas resistant shielded cables stand at the forefront, offering enhanced safety and reliability in hazardous environments. These cables, a critical component in the infrastructure of refineries, are designed to withstand extreme conditions, including exposure to oils, chemicals, and high temperatures.

This article explores the latest advancements in gas and oil resistant shielded cables, questioning, "What are the newest developments in this field that are elevating refinery safety standards?" By delving into this topic, this article aims to shed light on how these cables ensure operational efficiency and significantly contribute to the overall safety of refinery personnel and facilities. The focus on innovative solutions by industry leaders like our company, Windy City Wire (WCW), highlights a commitment to elevating safety standards and adapting to the evolving challenges within the oil and gas sector.

Enhancing Protection: Oil & Gas Fire-Resistant Cables

In the high-stakes arena of refinery safety, oil & gas fire-resistant cables are pivotal. These specialized cables are engineered to endure the extreme heat and potential fire hazards in refinery environments. Our company, Windy City Wire (WCW), has been at the forefront of this innovation, designing cables that meet and exceed industry standards for fire resistance.

The cables' construction incorporates resilient materials capable of withstanding direct flames, high temperatures, and corrosive chemicals, guaranteeing continuous operation during critical circumstances. These cables are critical components of suppression systems and fire alarms, among others, and play an indispensable role in preventing catastrophes.

Our oil & gas fire-resistant cables are about withstanding extreme conditions and enhancing overall safety measures. By incorporating advanced insulation and shielding techniques, these cables minimize the risk of electrical faults, a common cause of fires in refineries. Moreover, our company’s commitment to quality assurance and rigorous testing ensures that each cable batch upholds the highest safety standards. Such dedication to safety is transformative, making Windy City Wire’s fire-resistant cables a standard-bearer in refinery safety advancements and providing peace of mind to operators and engineers alike.

Temperature Resilience: High-Temperature Gas & Oil Resistant Wires

Temperature resilience is a critical factor in refinery operations, where extreme heat can compromise equipment integrity and safety. Dealing with this challenge, Windy City Wire (WCW) has created High-Temperature Gas & Oil Resistant Stranded Pair Wires showcasing our commitment to cutting-edge cable technology. These wires are specifically engineered to withstand the harsh conditions of refineries, where temperatures can soar to extreme levels, posing significant risks to equipment and personnel.

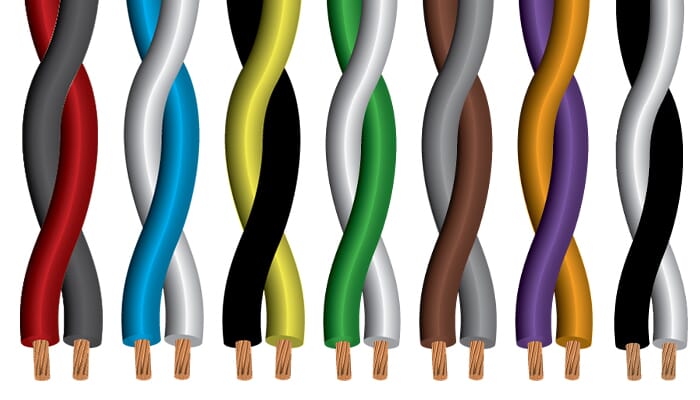

Windy City Wire stranded pair wires are designed with high-temperature oil and gas resistant materials that ensure performance stability even in the most severe conditions. The unique composition of these wires allows them to maintain electrical integrity and functionality, reducing the risk of malfunctions that could lead to hazardous situations. This resilience is particularly important in areas where cables are exposed to high ambient temperatures, near furnaces, or in areas with significant thermal radiation.

Significant progress in refinery safety has been made with the introduction of these high-temperature-resistant wires by Windy City Wire. By providing a solution that can endure intense heat without compromising performance, Windy City Wire contributes to safer refinery operations. Our commitment to innovation in this field underscores the importance of evolving safety measures to match the demanding environments of the oil and gas industry.

Setting Standards: Oil-Resistant Cables in the Industry

Central to enhancing refinery safety is the adherence to rigorous standards and certifications for oil-resistant cables. Oil-Resistant Triad Solid Cables manufactured by Windy City Wire (WCW) establish a solid standard in this field. These cables are not just built to resist oil and chemical exposure but are also designed in compliance with stringent industry standards. Such standards ensure that cables maintain structural integrity and performance, even in prolonged contact with harsh substances common in refinery settings.

Our company’s, commitment to quality is evident in our Oil-Resistant Triad Solid Cables. These cables undergo rigorous testing for resistance to oil, abrasion, and extreme temperatures, ensuring their durability and longevity in challenging environments. Compliance with industry standards like UL and IEEE ensures that these cables meet the highest safety and quality benchmarks.

This adherence to standards is not just about meeting regulatory requirements; it's a testament to our company’s dedication to providing products that enhance safety and reliability in the oil and gas sector. By focusing on standards and certifications, Windy City Wire ensures product excellence and contributes to setting industry-wide expectations for safety and performance in refinery operations.

Windy City Wire: Pioneering Solutions in Refinery Safety

Windy City Wire (WCW) stands at the forefront of refinery safety with our pioneering advancements in oil and gas resistant shielded cables. Our company demonstrates a relentless commitment to enhancing the safety and efficiency of refinery operations through our innovative fire-resistant, high-temperature, and oil-resistant cables. Each product reflects Windy City Wire’s commitment to dependability and quality through rigorous testing and adherence to industry standards.

Our company’s expertise and innovative offerings in the oil and gas industry are not just products; they are a promise of safety, efficiency, and resilience. As this article explores the evolving landscape of refinery safety, WCW’s role is pivotal in setting new benchmarks for safety and performance.

Our comprehensive solutions in low-voltage wire and cable address the unique challenges faced by the sector, making them a trusted and essential partner in the industry. Our company, Windy City Wire, is the preferred choice for refinery operators in search of state-of-the-art cable technology to enhance their operations.