Fueling the Future With Gas and Oil Resistant Shielded Cables

Revolutionizing Fuel Stations: The Critical Role of Gas and Oil Resistant Shielded Cables

The evolution of service stations and convenience stores has followed in an era where technology transforms routine operations at an accelerated rate. Oil and Gas resistant shielded cables are at the forefront of this revolution, vital yet often unnoticed components that power these modern facilities. These cables are the lifelines that ensure safe, efficient, and uninterrupted operations, from fuel dispensers to the digital displays that guide consumers.

Why are oil and gas resistant shielded cables so indispensable in today’s service stations? Their significance lies in their functionality and ability to withstand harsh environmental conditions, from extreme temperatures to chemical exposures. Their robustness ensures service stations remain operational, safe, and compliant with industry standards, making them an integral part of the infrastructure.

This article will explore the question, “What are the benefits of using oil-resistant cables in manufacturing?” As we delve deeper into the world of service stations, let's explore how these cables contribute to a seamless and secure experience for operators and customers, truly fueling the future of energy distribution.

Enhancing Efficiency: The Use of Throttle Cables in Fuel Systems

At the heart of a service station's efficiency and safety lies the unassuming but crucial throttle cable. These cables are pivotal in ensuring fuel dispensing systems operate precisely and reliably. Throttle cables are designed to provide a responsive and controlled connection between the fuel dispenser and the control system.

This connection is critical for ensuring fuel is dispensed precisely and safely by regulating the flow rate and pressure. In an industry where even minor discrepancies can lead to significant financial losses or safety hazards, the precision of throttle cables becomes non-negotiable.

Moreover, throttle cables are engineered to withstand the rigorous demands of a service station environment. They are often exposed to various chemicals, including gasoline and oil, and must resist corrosion and wear. The durability of these cables ensures that service stations can operate continuously without frequent maintenance interruptions, thereby enhancing overall efficiency.

Incorporating throttle cables into service station operations also means embracing a higher safety standard. These cables reduce the risk of fuel spillage and leaks, critical concerns in any fuel handling environment. Throttle cables play a vital role in preventing accidents and environmental hazards by ensuring a secure and stable connection in fuel systems. In essence, throttle cables are not just components; they are the guardians of efficiency and safety in fuel systems. Their importance in service station operations cannot be overstated, making them essential for modern, fast-paced, and safety-conscious service stations.

Building Better: Benefits of Oil-Resistant Cables in Manufacturing

In the manufacturing sector, especially within service stations, using oil-resistant cables marks a significant advancement in ensuring durability and operational efficiency. These specialized cables are designed to resist the degrading effects of oil, grease, and other petroleum-based products, which are commonplace in service stations. The benefits of using oil-resistant cables in manufacturing are manifold and pivotal for the smooth operation of service stations.

First, oil-resistant cables exhibit enhanced longevity in harsh environments. Traditional cables can degrade quickly when exposed to oil, leading to frequent replacements and downtime. In contrast, oil-resistant cables maintain their integrity over time, reducing maintenance costs and increasing the reliability of the equipment they power. This durability is not just a matter of cost-saving but also of ensuring uninterrupted service to customers.

Second, the safety aspect of using oil-resistant cables is paramount. In environments where oil spills and exposure are common, the risk of cable deterioration leading to short circuits or fire hazards is significantly reduced with these cables. This ensures a safer working environment for employees and protects the equipment from potential damage.

Additionally, these cables offer flexibility and ease of installation, which is crucial in the often-complex layouts of service stations. Their ability to bend without cracking or losing their protective qualities makes them ideal for use in tight or moving parts of machinery.

Incorporating oil-resistant cables into the manufacturing process of service stations represents a strategic investment in safety, efficiency, and longevity. Their role in maintaining the seamless operation of service stations is a testament to their importance in the modern fuel distribution industry.

Staying Resilient: Industrial and Gasoline Resistant Cables

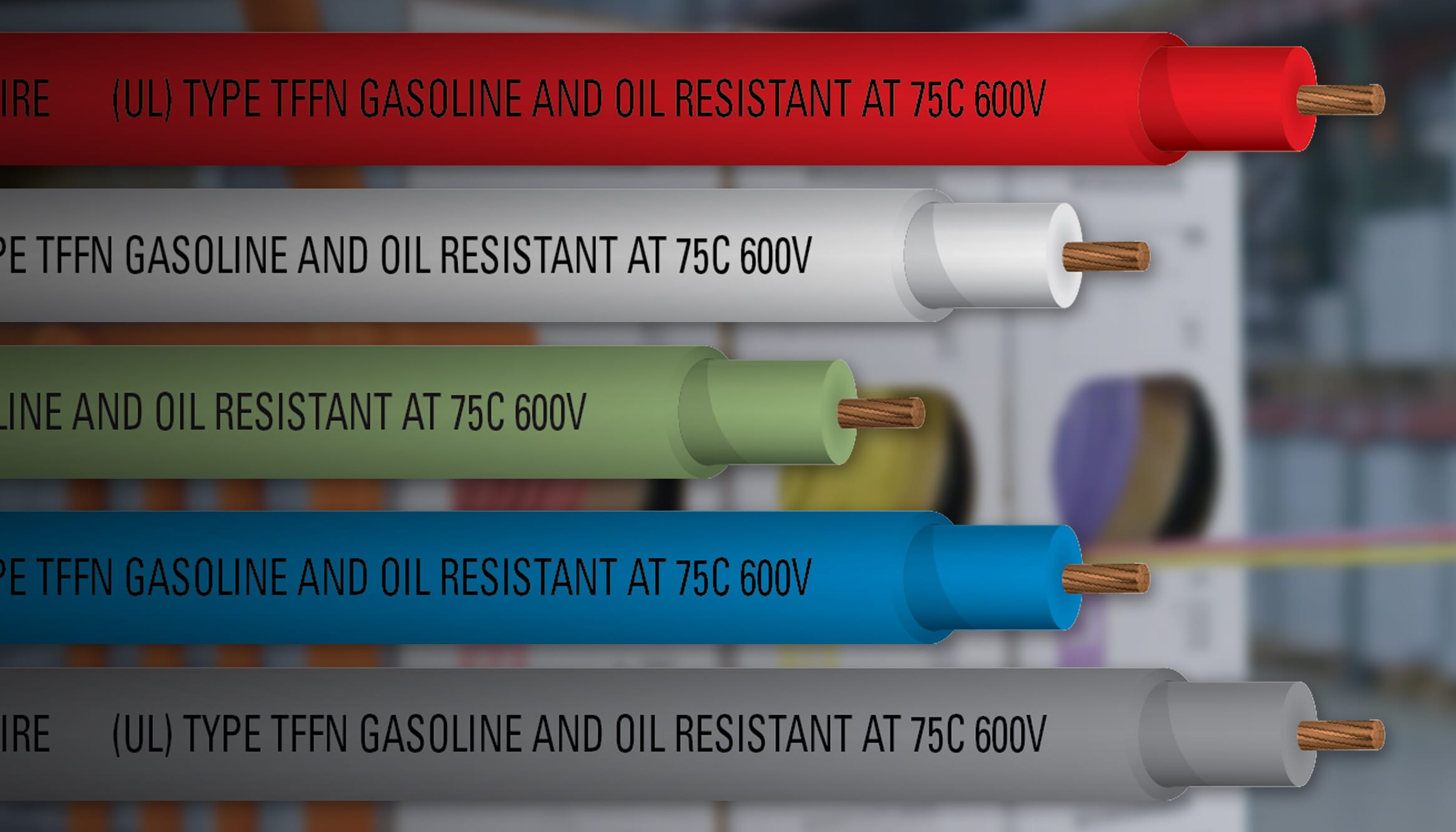

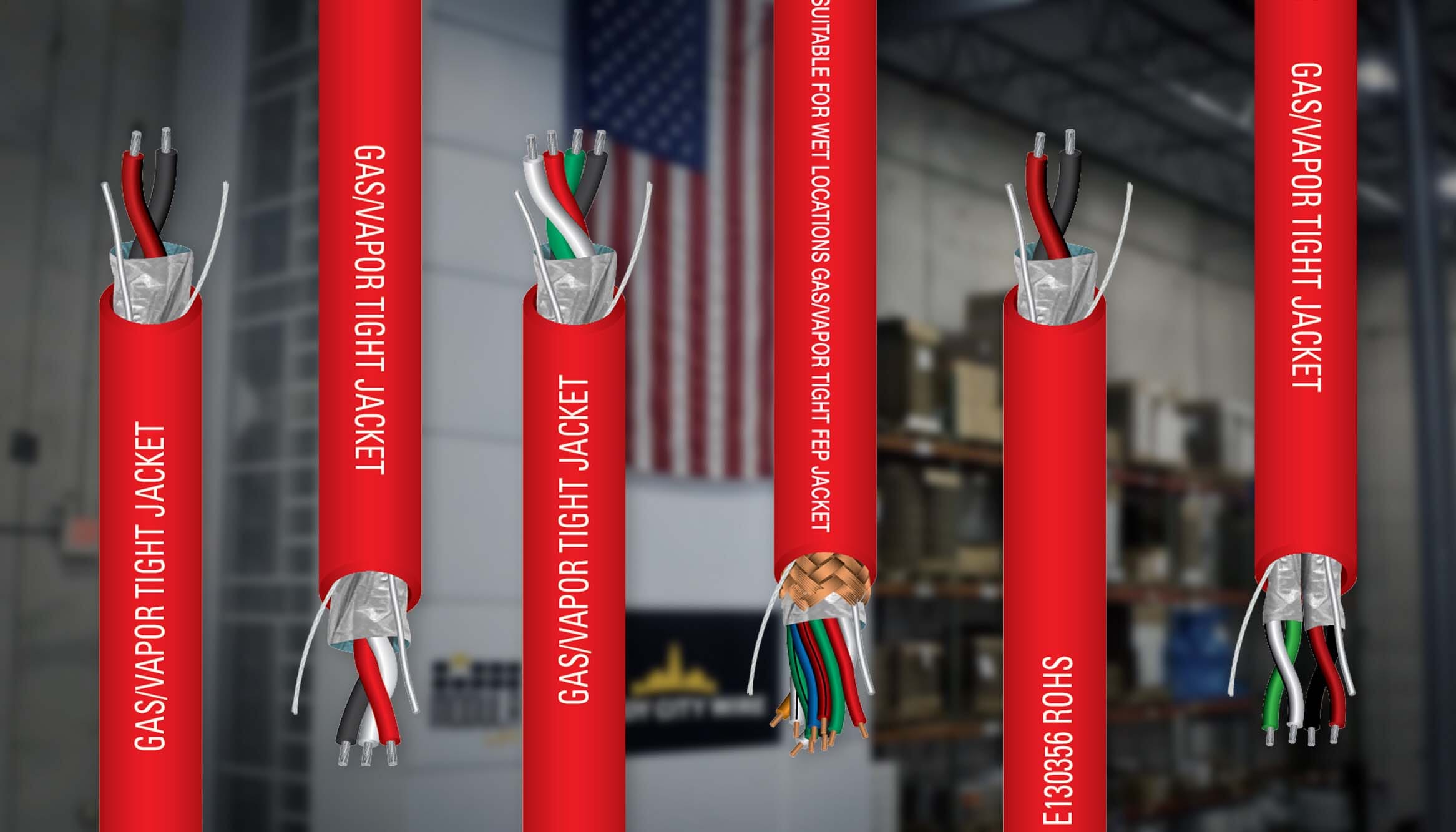

In the demanding environment of fuel systems, the resilience of cabling cannot be overstated. Industrial-Grade Stranded Cables and Gasoline Resistant Stranded Control Cables are testaments to this resilience. These cables are engineered to meet the unique challenges posed by fuel systems, ensuring uninterrupted and safe operations.

Industrial-Grade Stranded Cables, known for their robust construction, offer superior flexibility and durability. This flexibility is crucial in service stations, where cables must adapt to dynamic physical layouts and withstand constant movement and bending.

Moreover, Gasoline Resistant Stranded Control provide an added layer of protection. Their design specifically counters the corrosive effects of gasoline and other harsh chemicals commonly found in service stations. This resistance is critical in preventing cable degradation, which can lead to failures in fuel dispensing systems and pose significant safety hazards. These cables also feature advanced insulation and shielding technologies, which protect against electromagnetic interference (EMI) and ensure stable signal transmission. This is particularly important in today's service stations, where the integration of digital technologies demands reliable data transfer.

In summary, the use of Industrial-Grade Stranded Cables and Gasoline Resistant Stranded Control Cables in fuel systems is a proactive step toward ensuring safety, efficiency, and longevity. Their incorporation into service stations reflects a commitment to quality and reliability, safeguarding the infrastructure and the people it serves.

Windy City Wire: Powering Service Stations with Quality Cabling

We have discovered the critical functions of throttle cables, oil-resistant cables, and specialized stranded cables through our investigation of the complex world of service station cabling. Though often unseen, these components are fundamental to ensuring fuel systems' efficiency, safety, and resilience. Our company, Windy City Wire, stands at the forefront of this technological evolution, providing high-quality, low-voltage wire and cable solutions tailored to service stations and convenience stores' unique needs.

By choosing Windy City Wire, service stations invest not just in cables but in reliability, safety, and innovation. From the precision of throttle cables to the durability of oil-resistant and gasoline-resistant cables, our large exosystem of products embody the commitment to excellence that service stations require.

Owners, managers, and contractors of service stations are invited to experience the transformation that quality cabling can produce. Whether for new construction, renovations, or upgrades, Windy City Wire’s oil resistant and other specialized products are designed to meet the highest industry standards. Contact us today to learn how we can power your service station into the future, ensuring that your operations run smoothly, safely, and efficiently.