Deciding Between Field-Terminated and Pre-Terminated Fiber Optic Solutions

Choosing the right fiber optic cable termination type is essential when planning a network infrastructure project. The two primary options are field-terminated and pre-terminated fiber optic solutions. Each option has advantages and challenges that can impact project costs, setup time, and overall system performance.

We want to clarify the differences between these two approaches and provide you with the information needed to make an informed decision about your project. We will focus on critical considerations such as cost, setup time, and precision.

Understanding Field-Terminated Fiber Optic Solutions

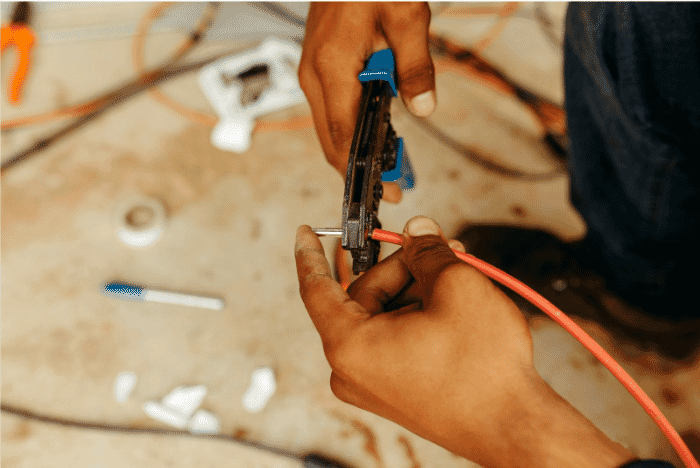

Field-terminated fiber optic solutions involve setting up and terminating fiber optic cables directly on-site. This process includes pulling cables between two points, attaching connectors at both ends and connecting them to a patch panel or network device. This approach allows for a high level of customization, as you can cut cables to the exact length required during setup. This flexibility is particularly beneficial in complex projects where precise measurements or network layouts may need adjustments.

However, field termination presents several challenges. It typically requires skilled technicians familiar with fiber optic technologies to cut, polish carefully, and fit connectors carefully. The need for specialized tools and training can increase labor costs. Additionally, the field termination process is more time-consuming than pre-terminated solutions, and there is a higher risk of human error, which could result in signal loss, poor performance, or even network disruptions.

Field-terminated fiber optic solutions are best suited for projects that demand on-site flexibility, such as projects in large or irregularly shaped buildings where cable paths cannot be predetermined. However, the potential for errors and longer setup times must be carefully considered against your project's specific needs and constraints.

Exploring Pre-Terminated Fiber Optic Cable

Pre-terminated fiber optic solutions simplify projects by providing cables already terminated with connectors in a factory setting. These cables arrive on-site ready for immediate use, which can significantly reduce the time required for setup.

The benefits of pre-terminated fiber cable are clear: they offer a straightforward setup process requiring minimal technicians' effort. Because the termination is done in a controlled environment, the likelihood of errors significantly shrinks. This level of accuracy can be especially advantageous in environments where consistent network connectivity is crucial, such as data centers or enterprise networks.

However, pre-terminated solutions also have certain limitations. Since the cables are cut to specific lengths, they require precise measurements and planning before setting up. Any miscalculations in length can lead to delays and additional costs, as new cables might need to be ordered. The lack of flexibility in adjusting cable lengths on-site also means that pre-terminated cables might not be ideal for projects with unpredictable or changing layout requirements.

Pre-terminated fiber optic cables are well-suited for projects where speed and accuracy are prioritized, and the network layout is well-defined in advance. These solutions help minimize set-up time and reduce the likelihood of errors, making them a preferred choice for many network projects.

Cost Comparison: Field-Terminated vs. Pre-Terminated

Cost plays a big role when choosing between field-terminated and pre-terminated fiber cable. Field-terminated fiber optic solutions generally involve higher upfront labor costs. The process requires skilled technicians, specialized tools, and extended setup time, which can add to labor expenses. However, field termination can be more cost-effective in some cases, especially when the flexibility to adjust cable lengths on-site can reduce material waste and accommodate changes in project scope without the need for new materials.

In contrast, pre-terminated fiber optic solutions often involve higher material costs, as the cables come pre-assembled and tested from the factory. The good news is that lower labor expenses and faster setup times frequently offset these costs. Since the termination process is done in a controlled environment, there is a lower risk of errors and less need for extensive testing and troubleshooting on-site. This can lead to cost savings in projects with high labor costs, or you must minimize downtime during setup.

While both options have their financial benefits and drawbacks, the decision should be based on the project's specific needs, including budget constraints, labor availability, and the importance of setup speed and precision.

Setup Time and Precision: Which Option is Faster and More Accurate?

Premade fiber optic cable generally provides a quicker setup when comparing setup times. These cables are ready to use upon arrival, significantly reducing the time spent on-site, particularly for large-scale projects or when time constraints are a concern. This makes pre-terminated solutions attractive for projects with tight deadlines or environments where minimizing disruption is essential.

While more time-intensive, field-terminated solutions offer flexibility and customization than pre-terminated cables. The precision required during the on-site termination can lead to delays, especially if technicians are not adequately trained or unexpected issues arise. However, this approach allows for more adaptability in projects where exact cable lengths or configurations are needed.

When deciding between these two options, speed and flexibility are vital considerations. Pre-terminated solutions provide a fast and accurate deployment method, while field-terminated solutions offer greater adaptability to each project's specific needs.

Applications and Decision-Making Framework

Both field-terminated and pre-terminated fiber optic solutions have their place in various network projects, and understanding their applications can help in making the right choice.

Field-terminated fiber optic solutions are often used in environments where flexibility is crucial, such as large or complex facilities where cable routes may change or need to be customized on-site. They are also suitable for projects where you cannot determine precise measurements in advance or need to run cables through tight spaces or complex pathways.

Pre-terminated fiber optic solutions are ideal for projects where the network layout is well-defined in advance and speed and precision are priorities. They get used in data centers, enterprise networks, and other environments where it is crucial to minimize setup time and reduce the risk of errors. The reduced need for on-site termination work also makes pre-terminated solutions a good choice for projects with limited access to skilled labor or where labor costs are high.

When deciding between these options, consider the project size, budget, timeline, and technical requirements. A decision-making framework can help evaluate these factors and determine the best solution for your needs.

Making The Final Choice

Choosing between field-terminated and pre-terminated fiber optic solutions requires consideration of various factors, including cost, setup time, and precision. Both options have strengths and limitations; the best choice will depend on your project's specific needs.

Field-terminated solutions offer flexibility and adaptability, making them suitable for complex projects with changing requirements. Pre-terminated solutions provide faster setup and greater accuracy, making them ideal for projects where it is essential to minimize setup time and reduce the risk of errors.

At Windy City Wire, we understand the importance of selecting the right fiber optic solution for your project. We offer various fiber optic cables, including field and pre-terminated options, to meet the needs of various industries and applications. Explore our selection of fiber optic solutions here and contact us for more information on choosing the right cables for your project.