A New Era of Fueling Systems With Gas and Oil Resistant Shielded Cables

The technologies that drive our industries are constantly evolving. Fueling systems have undergone a significant paradigm shift with the introduction of gas and oil resistant shielded cables, which signifies the beginning of a new era. These cables, known for their robustness and efficiency, have revolutionized how fueling infrastructures are designed and operated. They offer enhanced safety, reliability, and performance, crucial factors in an industry where precision and durability are paramount.

Let us delve into the significant role of advanced cable technology in shaping modern fueling systems. It raises a pertinent question: How have fueling systems evolved with the introduction of advanced cable technology? By exploring this question, this article aims to shed light on the technological advancements driving the industry forward and how they are being integrated into contemporary fueling systems.

Core Applications: The Role of Oil and Gas Cables

In the intricate landscape of modern fueling systems, oil and gas cables play a pivotal role. Their primary applications extend across various segments of the industry, driving efficiency and ensuring operational integrity. These cables are designed to withstand the harsh conditions typical in oil and gas environments, such as extreme temperatures, chemical exposure, and physical stress. One key application is transmitting power and data within drilling operations, where their durability ensures uninterrupted functionality.

Additionally, they are integral to offshore platforms, facilitating the safe and reliable transmission of power to remote locations. These cables also find critical use in refineries and petrochemical plants, where their resistance to oil and chemicals safeguards against potential hazards. The question "What are the main applications of oil and gas cables?" is not merely about their uses but also their impact on the industry. They contribute significantly to operations' safety, efficiency, and productivity, shaping the dynamics of modern fueling systems.

Industry Standards: Oil Resistant Wire Applications

The applications of oil-resistant wire in the industry are a testament to the sector’s commitment to safety, efficiency, and innovation. These wires, designed to withstand fueling systems' corrosive and abrasive environments, are crucial in maintaining uninterrupted operations. Fuel dispensing systems are essential for ensuring the safe and efficient flow of fuel, reducing the risk of leaks and spills. These wires are also employed in monitoring systems, where they transmit data crucial for the safe operation and maintenance of fueling infrastructure.

Another key application is in emergency shutdown systems, where the reliability of oil-resistant wires is critical for preventing accidents and ensuring the safety of personnel and equipment. The significance of these wires extends beyond their functional roles; they symbolize the industry's adherence to high safety and quality standards. By incorporating oil-resistant wires, the fueling industry demonstrates its readiness to adapt to technological changes, prioritizing operational efficiency, environmental responsibility, and safety.

Durability and Efficiency: The Rise of Gas-Resistant Cables

The increasing reliance on Gas-Resistant Triad Solid Cables underscores a major shift toward prioritizing durability and efficiency in fueling systems. The cable's durability is engineered to resist harsh chemical environments, particularly those prevalent in gas exposure scenarios, and has become integral to modern fueling infrastructure. Using such cables directly impacts the longevity and reliability of fueling systems.

These cables are crucial in environments exposed to volatile organic compounds and other corrosive gasses. They ensure uninterrupted power supply and data transmission, which is critical for monitoring and controlling fueling processes.

Additionally, their longevity decreases repairs and expenditures, thereby enhancing system performance. The rise of these cables is not just a technological advancement; it represents a commitment to safety, as their resistance to gas exposure significantly minimizes the risk of cable degradation and system failures. In essence, Gas-Resistant Triad Solid Cables are pivotal in enhancing the resilience and efficiency of fueling systems, addressing industry needs, and adapting to technological changes.

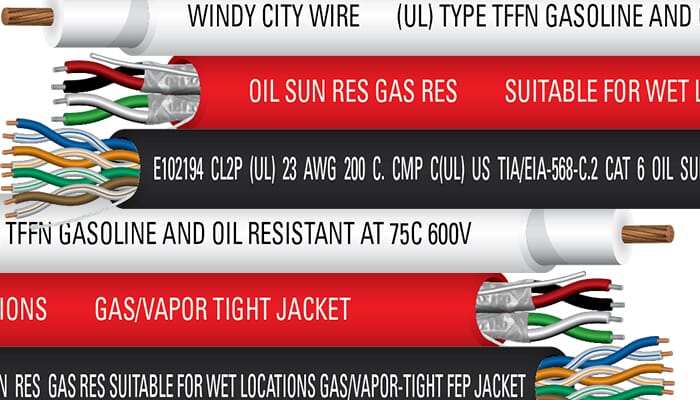

Windy City Wire: Leading Innovation in Fueling System Cables

The evolution of fueling systems in the age of gas and oil resistant shielded cables is a testament to the industry's commitment to innovation and safety. We at Windy City Wire are a leading company in the gas and oil industry, known for our extensive expertise and commitment to staying ahead of industry developments. Our innovative cable solutions, including Gas-Resistant Triad Solid Cables, demonstrate a deep understanding of industry needs and challenges.

Our company, Windy City Wire, focuses on delivering comprehensive low-voltage and solutions tailored to enhance the efficiency and safety of fueling systems, which sets us apart as a leader in the field. Windy City Wire provides the products and services required by system designers, engineers, and consultants in the fueling industry to navigate the dynamic terrain of fueling infrastructure effectively. Contact Windy City Wire for all your gas and oil wire and cabling needs. We are committed to embracing the future of fueling systems with confidence and innovation.