A Deep Dive About How Skin Effect Impacts Cable Performance

We’ve spent years working with various types of cables and dealing with the complexities of signal transmission. The skin effect is one of this field's most fascinating yet often misunderstood phenomena. There can be debates about why high-frequency signals aren’t performing as expected. Once professionals can appreciate the nuances of the skin effect and its profound impact on cable performance, it all becomes clearer.

We at Windy City Wire want to demystify the skin effect, explain its significance, and highlight how choosing the right cables can make a substantial difference in your projects.

What is Skin Effect?

The skin effect occurs in conductors when an alternating current (AC) flows through them. At its core, the skin effect refers to the tendency of AC to distribute itself within a conductor so that the current density is highest near the conductor's surface and decreases with greater depths. This effect becomes more pronounced at higher frequencies.

In simple terms, when a signal travels through a conductor, the AC signal prefers the path of least resistance along the conductor's outer surface. This results in the inner parts of the conductor being underutilized for high-frequency signals, which can affect the overall efficiency and performance of the cable.

The Science Behind Skin Effect

To understand the skin effect in detail, let’s look into the science behind them.

Current Distribution: In a direct current (DC) scenario, the current is uniformly distributed across the entire cross-section of the conductor. However, as the frequency of the AC signal increases, the current starts to shift towards the conductor's surface. This phenomenon is due to the formation of eddy currents within the conductor, which create opposing magnetic fields and push the current outward.

Skin Depth: The term "skin depth" refers to the depth below the conductor's surface where the current density drops to about 37% of its value at the surface. Skin depth is inversely proportional to the square root of the frequency of the AC signal and the electrical conductivity and magnetic permeability of the conductor. The formula for calculating skin depth (δ) is:

δ= Square root (2ρ/ωμ)

Where:

- ρ is the resistivity of the conductor

- ω is the angular frequency of the AC signal

- μ is the magnetic permeability of the conductor

For instance, at 20 kHz, the skin depth for copper is approximately 18.4 mils (0.0184 inches). This means that a significant portion of the conductor’s interior is not effectively utilized to carry the current for higher frequencies.v

Table and Graph Analysis:

Conductor Size Diameter (inches) % of Conductor Used at 20 kHz 24 AWG 0.024 100% 22 AWG 0.031 100% 12 AWG 0.093 75% 10 AWG 0.115 68%

Impact of Skin Effect on Different Cable Types

The impact of skin effect varies depending on the cable type and its intended application. Understanding this is crucial for selecting the right cable for your needs.

Audio Cables:

The skin effect is negligible for low-frequency audio signals. The frequencies involved are typically below 20 kHz, meaning the entire cross-section of the conductor is used effectively. This keeps the signal integrity high without significant losses due to the skin effect.

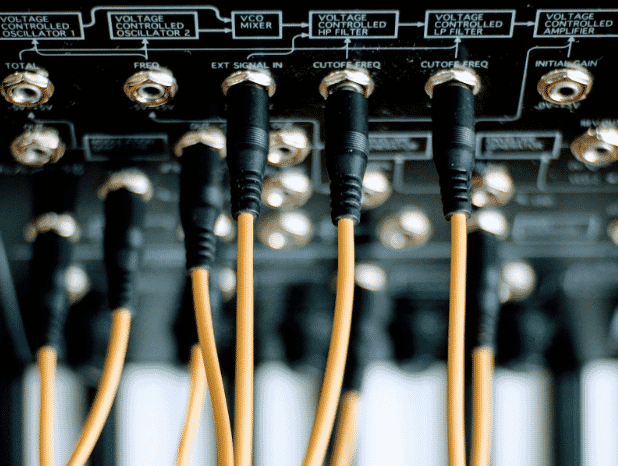

Digital and High-Frequency Cables:

In contrast, digital and high-frequency cables, such as those used for video signals or data transmission, are significantly affected by skin effect. At higher frequencies, the current is confined to a thin layer near the conductor's surface, reducing the effective cross-sectional area and increasing the resistance. This can lead to signal degradation and higher attenuation, impacting the cable's performance.

Broadband and CATV Cables:

Skin effect becomes critical for broadband and CATV applications, which operate at frequencies well into the hundreds of MHz. These cables often utilize designs that account for skin effect, such as using copper-clad steel conductors. The steel core provides mechanical strength, while the copper coating provides good conductivity at high frequencies where the skin effect predominates.

Mitigating Skin Effect

While the skin effect is a natural phenomenon, there are ways to mitigate its impact on cable performance. These include selecting appropriate cable designs and materials, using techniques like litz wire to reduce losses at high frequencies, and employing high-quality manufacturing processes to allow optimal conductor surfaces.

Cable Design

One of the most effective ways to reduce the impact of skin effect is through thoughtful cable design. Manufacturers often use cables with smaller strands of wire twisted together for high-frequency applications, known as litz wire. This design increases the surface area available for the current to flow, thus reducing the overall resistance and minimizing signal loss.

Material Selection

The choice of conductor material also plays a significant role. Copper and aluminum are commonly used because of their excellent conductivity. Copper-clad aluminum or copper-clad steel may be used for high-strength and flexibility applications. These materials combine copper's conductivity with aluminum or steel's mechanical benefits, optimizing performance in environments where skin effect is a concern.

Manufacturing Techniques

Advanced manufacturing techniques can improve the conductor's surface quality, ensuring that the outer layer, which carries most of the current at high frequencies, is as smooth and defect-free as possible. Electroplating and annealing can improve the conductor's performance by creating a uniform and highly conductive surface.

Choosing the Right Cable for Your Application

Selecting the appropriate cable for your specific application is important for optimal performance and mitigating the adverse effects of skin effect. Here are some guidelines to help you make an informed decision:

Audio Applications

For low-frequency audio applications, skin effect is less of a concern. However, choosing cables with high-quality copper conductors and proper shielding can help minimize signal loss and high fidelity. Look for cables designed for audio applications, often including features to minimize electromagnetic interference (EMI) and radio frequency interference (RFI).

High-Frequency Digital and Video Applications

In high-frequency applications, such as digital video and data transmission, the skin effect's impact is more pronounced. For these uses, select cables designed to handle high frequencies efficiently. Coaxial cables and twisted pair cables with solid copper or copper-clad conductors are excellent choices. Check that the cables are rated for the specific frequencies and data rates your application requires.

Broadband and CATV Applications

For broadband and CATV applications, which operate at frequencies ranging from hundreds of MHz to several GHz, cables must be designed to maintain signal integrity over long distances. Look for cables with copper-clad steel conductors, which provide the necessary strength and conductivity. Additionally, the wires have dependable shielding to prevent signal degradation due to external interference.

Industrial and Control Systems

Selecting the suitable cable is critical in industrial environments, where cables may be exposed to harsh conditions. Direct burial cables with rugged jackets and water-blocking fillers are ideal for underground installations. For control systems, consider cables with high resistance to environmental factors and strong mechanical properties to withstand physical stress.

A Final Look at How Skin Effect Impacts Cable Performance

Understanding the skin effect and its impact on cable performance is essential for anyone designing and maintaining communication and power systems. By appreciating how skin effect influences signal transmission, you can make better-informed decisions about the cables you choose for your projects.

The right cable can make all the difference, from providing high-fidelity audio transmission to maintaining strong data integrity in high-frequency applications. We offer a wide range of cables designed to meet the needs of various applications, from audio and video to industrial control systems and broadband communications.

By leveraging advanced cable designs, high-quality materials, and state-of-the-art manufacturing techniques, you can mitigate the adverse effects of skin effect and enjoy optimal performance.