5 Ways Gas and Oil Resistant Cables Boost Industrial Efficiency

In industrial settings, reliability and efficiency are essential. Standard cables don't always face the challenge of harsh environments like extreme temperatures, high mechanical stress, or exposure to corrosive substances. That’s where gas and oil-resistant cables come in.

We understand the importance of minimizing disruptions, enhancing safety, and streamlining operations at Windy City Wire. These cables resist degradation, withstand tough conditions, and reduce the need for maintenance, making them an essential investment for boosting operational efficiency. Here are five key ways gas and oil-resistant cables improve industrial productivity and resilience.

Ensuring Durability in Extreme Conditions

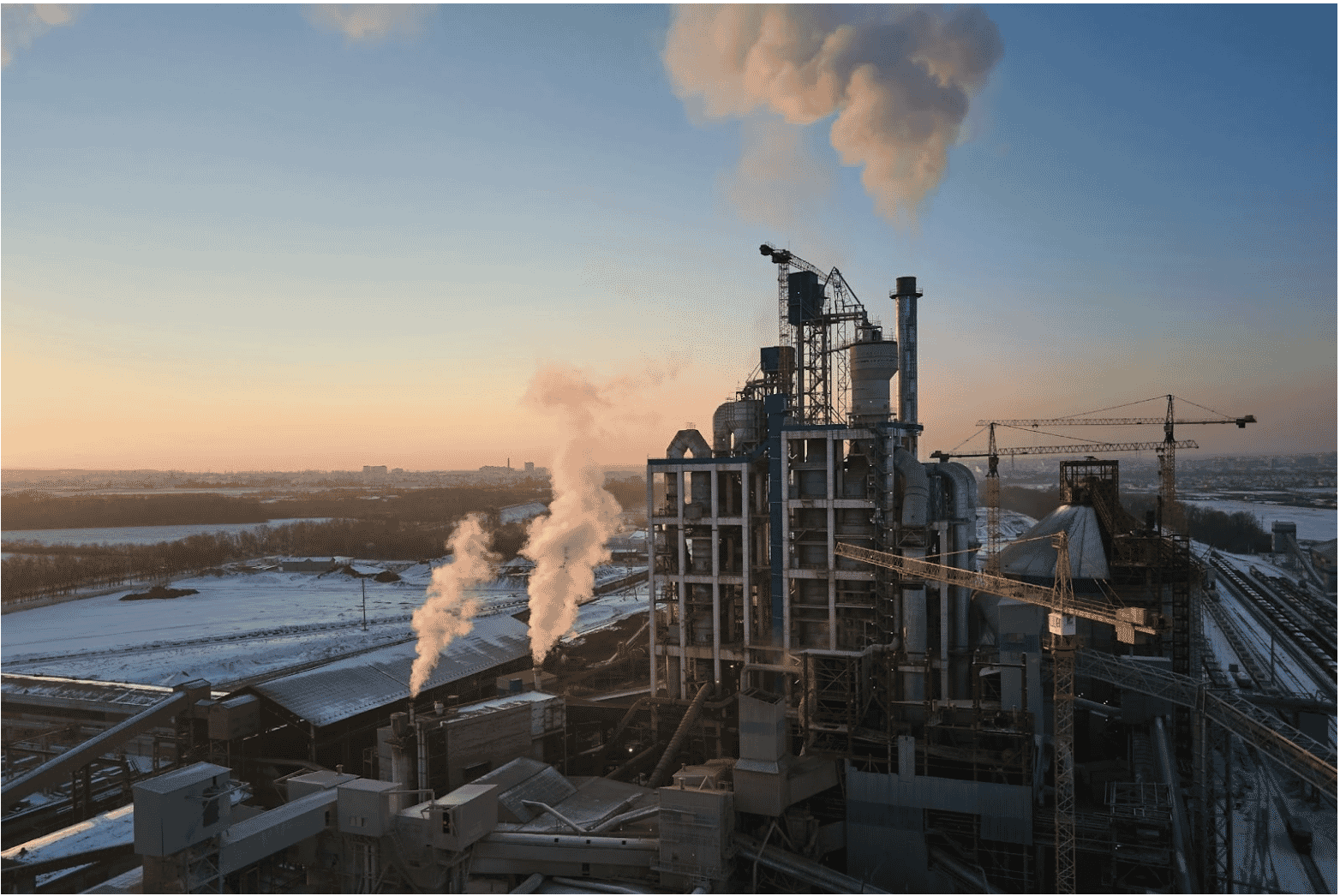

The longevity of materials matters in harsh industrial settings. Gas and oil-resistant cables can withstand extreme temperatures, exposure to corrosive substances, and mechanical stress. Unlike standard cables, these oil-proof industrial cables have robust insulation that resists chemical reactions with oils, fuels, and other volatile compounds commonly encountered in heavy-duty environments like oil refineries, chemical processing plants, and gas production facilities.

This durability comes from the materials used in the cable jackets, specifically designed to prevent the ingress of chemicals and moisture and to resist high temperatures. As a result, these cables can endure wear and tear from chemical exposure and abrasive materials without experiencing performance degradation.

The result? Fewer disruptions are caused by cable failure and longer-lasting projects. This advantage becomes especially clear in applications where equipment failure is costly or dangerous, like manufacturing plants, where a breakdown could cause costly downtime or safety risks.

By using gas and oil-resistant cables, companies extend the lifecycle of their cabling and build resilience into their operations, ensuring a more reliable infrastructure even in the most challenging conditions.

Reducing Downtime and Maintenance Costs

Frequent cable replacements and repairs can drain resources, time, and money. Chemical-resistant wiring solutions last longer, meaning they don’t need to be replaced as frequently as standard cables. This reduced need for replacement decreases direct costs associated with parts and labor and reduces unplanned downtime, allowing facilities to operate more smoothly and consistently.

Heavy-duty oil-resistant cabling excels at minimizing wear and tear. Their advanced coatings resist the buildup of contaminants, which means they don’t break down as quickly. This significantly reduces maintenance schedules for industries that can’t afford frequent interruptions, like oil production, heavy manufacturing, and chemical processing plants. With fewer interruptions and a more streamlined maintenance process, operational flow improves, making these cables an investment that pays off over time.

For industries that rely on uptime to maintain profitability, this enhanced reliability and cost savings from reduced maintenance help maximize the productivity of every shift. The initial investment in gas and oil-resistant cables quickly balances out when considering the cost of replacements, repairs, and downtime with standard cables.

Enhancing Safety in Industrial Environments

When it comes to industrial environments, safety is always a top priority. Facilities that handle combustible materials, heavy machinery, and electrical systems are often high-risk areas, and the presence of volatile chemicals makes safety even more critical. Gas and oil-resistant cables function reliably without compromising their integrity, even in the presence of aggressive substances. These cables reduce the risk of leaks, short circuits, and fires—helping maintain a safer work environment.

Additionally, many cables meet strict safety standards and regulations for oil refineries, chemical manufacturing plants, and other industrial sites. By selecting the right cables, companies can help reduce the risks of electrical failures and ensure that equipment and processes operate safely. This proactive approach to safety means less worry about compliance with industrial safety standards, as these cables meet or exceed regulatory expectations for safety in volatile environments.

Ultimately, oil and gas-proof electrical cables aren’t just about keeping things running smoothly; they’re about protecting the people and assets within a facility. These cables are an important part of any comprehensive safety strategy, as they minimize the potential for electrical failures, leaks, or fire hazards.

Optimizing Operational Efficiency

The right cable selection can substantially impact overall operational efficiency. Consistent power delivery and reliable data transmission are essential in systems where uptime is necessary, such as energy production, heavy manufacturing, and transportation. Gas and oil-resistant cables excel in these areas because they’re less likely to degrade, corrode, or experience interruptions that could slow down or halt operations.

Imagine a factory where every machine and process relies on power and data cables to function. If a standard cable is compromised by oil exposure or chemical damage, the entire production line could be delayed, affecting productivity, timelines, and profitability. With gas and oil-resistant cables, companies can ensure that their equipment stays online, maintaining an uninterrupted flow that supports efficiency and output.

At Windy City Wire, we provide cables that directly optimize operational flow. This reliability means that teams can focus on meeting production targets without troubleshooting cabling issues. These cables keep the power on and the data moving, helping companies meet their goals more consistently.

Versatility Across Multiple Applications

One of the greatest strengths of gas and oil-resistant cables is their adaptability to various industries and applications. From energy production and automotive manufacturing to industrial transportation and heavy equipment, these cables are trusted in diverse environments that demand reliability and durability.

For instance, in automotive plants where assembly lines are exposed to oils, lubricants, and other fluids, these cables maintain performance without degradation. Similarly, gas and oil-resistant cables work in outdoor and indoor projects in energy production facilities, where extreme temperatures, chemical exposure, and physical stress are constantly challenging. Their ability to adapt to different environments and withstand varied conditions allows for versatility, providing a one-size-fits-most solution for industries that need flexible, durable options.

This versatility offers businesses the convenience of standardized cabling solutions across multiple facilities and sites without worrying about premature breakdowns due to incompatible materials. Gas and oil-resistant cables meet the needs of different industries while providing a reliable infrastructure that helps simplify maintenance and reduce costs. These cables are invaluable for companies looking to streamline operations with cables that can handle harsh conditions.

Boosting Industrial Efficiency

Gas and oil-resistant cables benefit industrial operations by enhancing durability, reducing downtime, improving safety, and optimizing operational efficiency. Their versatility across multiple applications further solidifies their importance in environments where standard cables may not be up to the task. We offer solutions that help businesses maintain efficient, resilient operations.

Whether in energy production, manufacturing, or another industry with demanding requirements, we have cable solutions tailored to your needs. Contact us to learn how gas and oil-resistant cables can enhance your industrial setup, streamline operations, and provide peace of mind. Investing in the right cables can be a game-changer for maintaining efficiency and safety, and we’re excited to help you make that choice with confidence.